Product

Self Cleaning Filter

Our Advantage

Solid wooden packaging.

Free CAD or 3D drawing available.

Can customize according to customer’s request.

High quality filter element and transmission system.

Siemens or SEW motors to ensure the operation stability.

Schneider or Siemens control system with multi-language display.

Stcriclty selected steel supplier to ensure the stable quality and price.

Independent research and Autonomous production of key component to ensure equipment quality.

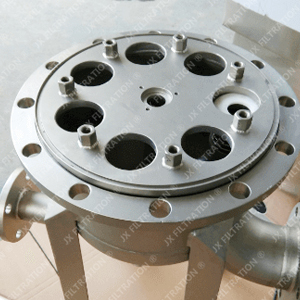

Self Cleaning Filter

Description

Self Cleaning Filter is designed for high-viscosity liquid filtration. It can effectively remove impurities on the surface of filter screen through mechanical scrapping and filter screen is cleaned automatically by time/differential pressure. Filter precision from 30 to 1500micron.

Self Cleaning Filter allows for continuously online filtration without generation of filtration consumables and the need of manual cleaning.

Best Factory, Best Product. Contact Now !!!

Four Subseries

● Inner scraper type: designed to remove impurities on the inner surface of filter screen through scraper rotation driven by motor. It applies to the filtration in medium and highly viscosity liquids.

● Outer scraper type: designed to remove impurities on the outer surface of filter screen through scraper rotation driven by motor. It applies to the filtration in highly viscosity liquids.

● Brush scraper type: designed to remove impurities on the inner surface of filter screen through rotation of scraping brush driven by motor. It applies to the filtration in low viscosity liquids.

● Cylinder scraper type: designed to remove impurities on the inner surface of filter screen through vertical movement of scraper driven by air cylinder. It applies to the filtration in medium and highly viscosity liquids, and inflammable and explosive occasions.

Application

Water, cooling liquid, edible oil, paint, resin adhesive, ink, pigment, polymer, kerosene, citric acid, fermentation broth, protein, soap, sorbitol, wet-end additive, rubber, ethanol, chocolate, candy, high temperature oil, fruit juice, diesel, ect.

Self Cleaning Filter

Related Product

Self Cleaning Filter

Related Cases

Product

Self Cleaning Filter

FAQ

Where is your factory?

We have three factories in Sichuan, Hebei, Jiangsu. Because the difference of customer locations, raw material price, factory wages and other considerations. In this way, we can provide the best quality product with lower cost.

Do you have a certification?

Yes. we have ISO/CE/BV/SGS/TUV certificate and patent certificate.

How about the delivery time?

Usually 1-15 days after prepayment is confirmed.

Do you have a design team?

Yes, we have. Providing drawing, electric drawing and others.

What is your payment?

T/T, L/C, Western Union, Paypal.

Can you provide certificate of origin?

yes, we can provide CO as well as FORM E, FOEM F and etc.

Can you accept OEM?

Yes, we could do OEM for you.

Can you send me a sample?

Yes.1-3 days for delivery.

Self Cleaning Filter

Our Service

Professional Pre-sale

Service

Filtration method and

equipment recommendation.

Free CAD or 3D

drawing provided.

Free phone call.

Complete Service

During Sales

On time delivery.

Equipment inspection

by photo or video.

Secure and standard

package provided.

After Sales Service

Installation assist by

phone call or video.

Free accessories provide

for maintenance.

Engineer sent for

solving onsite problem.